INDUSTRY NEWS

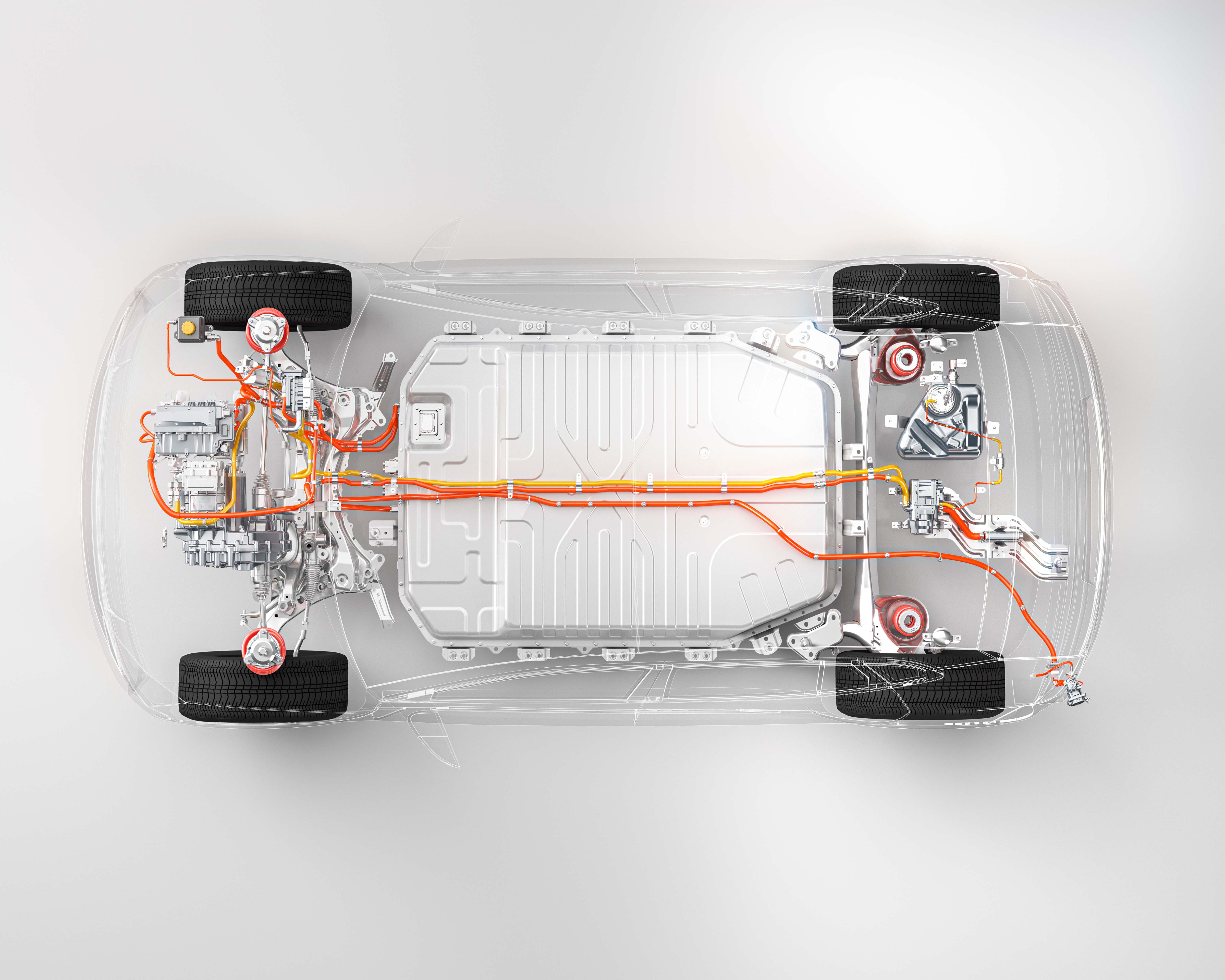

End of the Blue-Foil Era? Lankwitzer UV Coating Charges Ahead in the 800 V Race

In 2018, BMW fired up the world’s first mass-production line for battery “UV-insulation...

GB 38031-2025 New National Standard is Approaching: How Does UV Coating Technology Lead the Safety Upgrade of Power Batteries?

In response to the "strictest-ever battery safety regulations,Lankwitzer , a global...

UV Coating for Lithium Batteries

The Advantages of UV Technology in Battery Applications...

A Key Driver for Green Transformation in the EV Industry Chain

Lankwitzer’s VOC free coatings, as a critical component in the green transformation of the new energy vehicle (NEV) industry chain, are leading the sector toward a greener ...

Battery Electrode Coating Cost: Navigating the Path to Affordable and High - Performance Solutions

This article explores the various factors influencing battery electrode coating cost and how manufacturers are finding ways to balance expense with performance. It highlights Lankwitzer’s strategies in reducing costs while maintaining high - quality coating standards.

Custom Battery Coating Solutions: Meeting Diverse Demands with Precision

This article explores how custom battery coating solutions address the unique requirements of various industries. It details the significance of tailored coatings in enhancing battery performance, and showcases Lankwitzer’s expertise in delivering innovative and high - quality custom solutions.

UV battery coating - an innovative choice for protecting new energy batteries

UV battery coatings, as key materials for the protection of new energy batteries, play a significant role in enhancing battery safety and performance. This article will introduce the advantages of UV battery coatings and the innovative achievements of enterprises, with a focus on showcasing the technologies of companies such as Lankwitzer, to help understand the dynamics in this field...

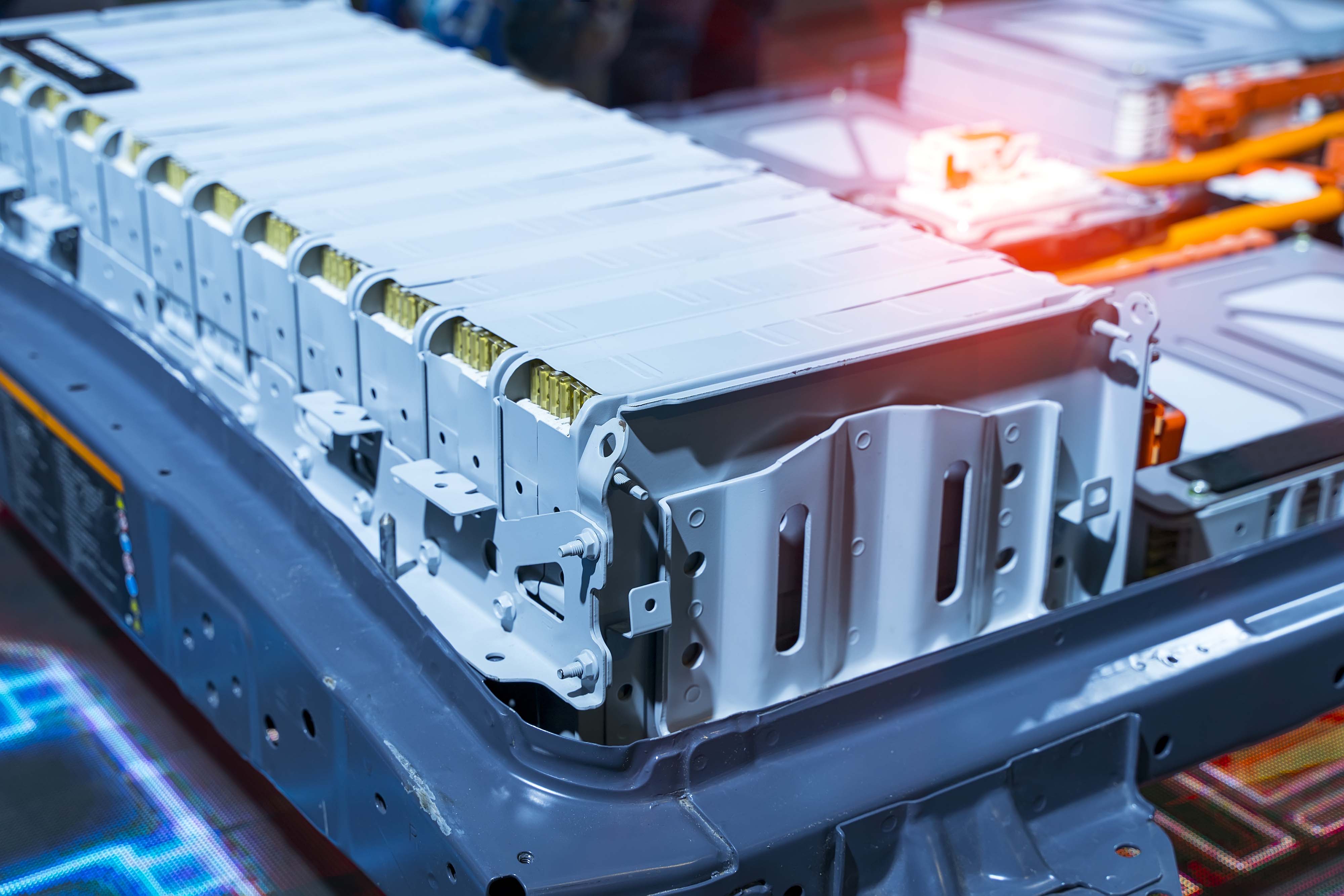

Cell insulation material: the cornerstone of safety and performance of new energy batteries

In the booming new energy industry, cell insulation materials play a crucial role in ensuring the safe and stable operation of batteries. This article will delve into the importance of cell insulation materials, detail the innovative achievements of various companies in this field, and highlight the outstanding contributions of companies like Lankwitzer, aiming to provide readers with a comprehensive understanding of the development trends in the field of cell insulation materials...

Lithium Battery Coating Process Optimization: Elevating Performance Through Precision

This article explores how optimizing the lithium battery coating process is key to enhancing battery performance, safety, and lifespan. It details the critical aspects of process refinement and highlights Lankwitzer’s innovative approaches in driving industry - leading improvements.

Battery Coating Manufacturer: Pioneering the Future of Energy Storage

This article explores how battery coating manufacturers are instrumental in shaping the energy storage landscape. It details their contributions to improving battery performance, safety, and efficiency, with a spotlight on Lankwitzer’s innovative solutions and technological leadership.